Sail Repairs | South East Asia Sails (SEA Sailmakers)

At South East Asia Sails (SEA Sailmakers), we understand that a well-maintained sail is key to a successful and enjoyable sailing experience. While high-quality sails are built to last, wear and tear are inevitable, especially when cruising remote islands and challenging waters. Our sail repair services are designed to keep your sails in top condition, ensuring you can sail with confidence no matter where your journey takes you.

Comprehensive Sail Repair Services

Our expert team at SEA Sailmakers offers a full range of sail repair services to address any issues you may encounter. Whether it's a minor rip or a major tear, we are equipped to handle repairs of all sizes with precision and care. Our services include:

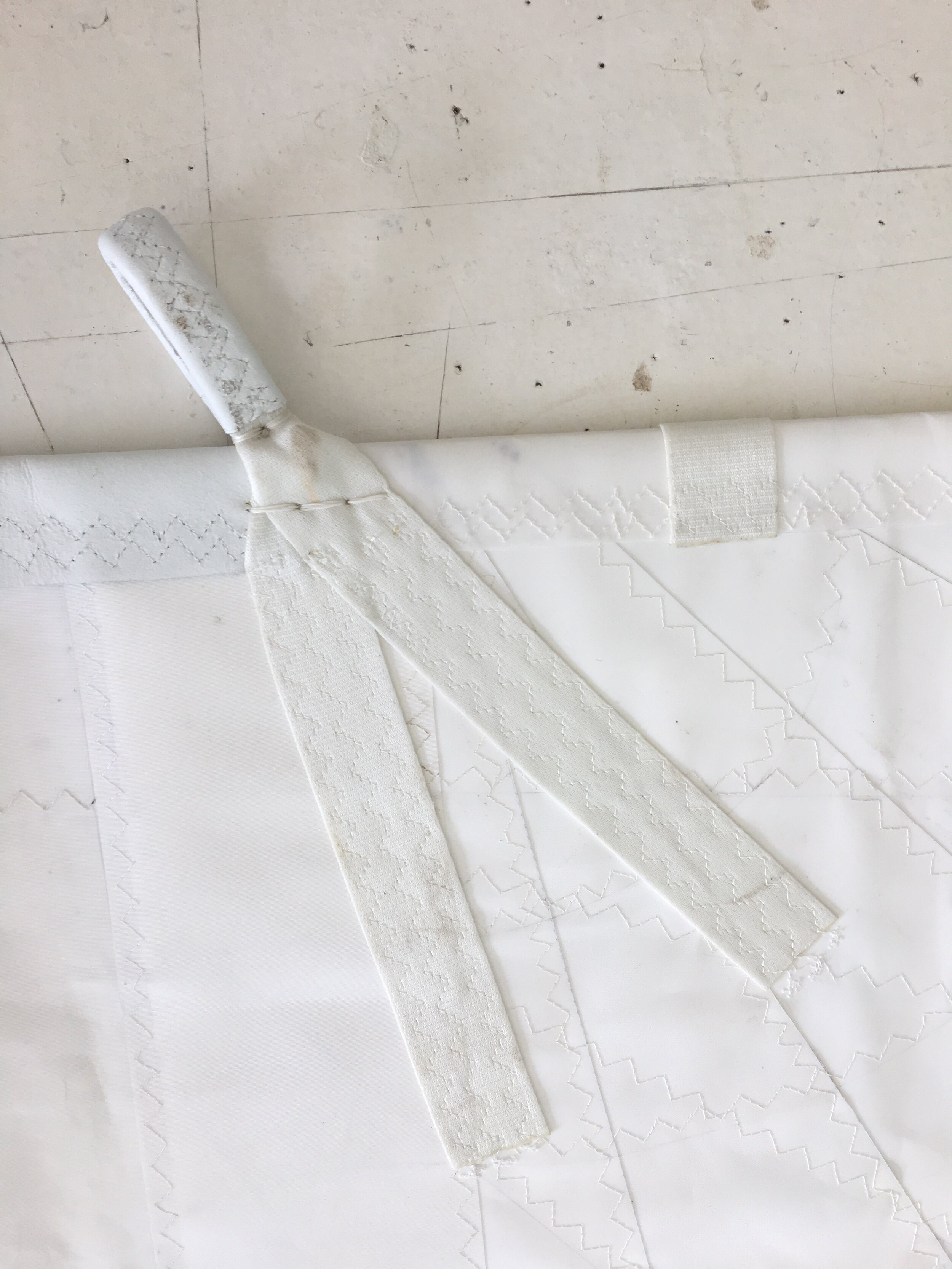

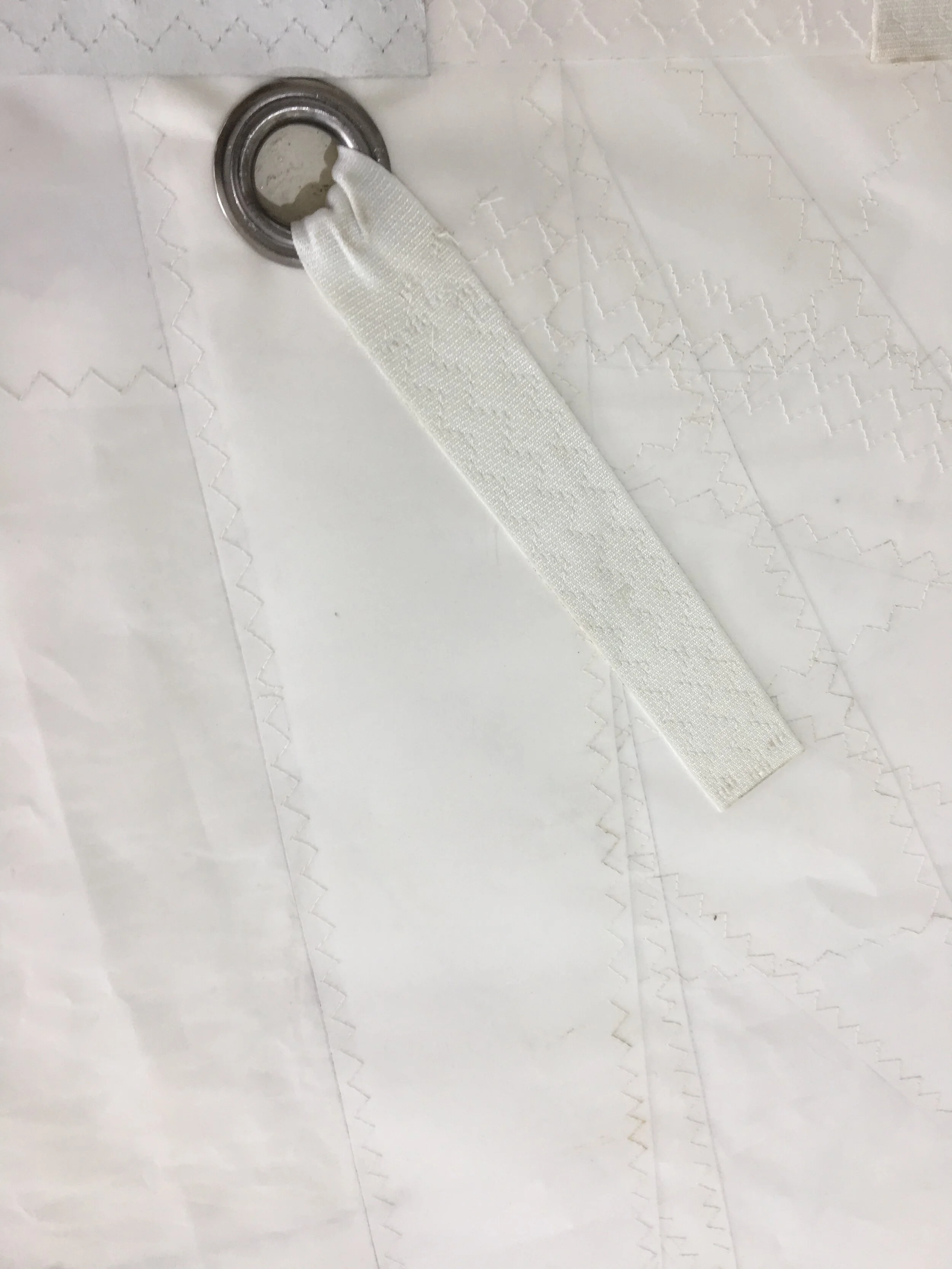

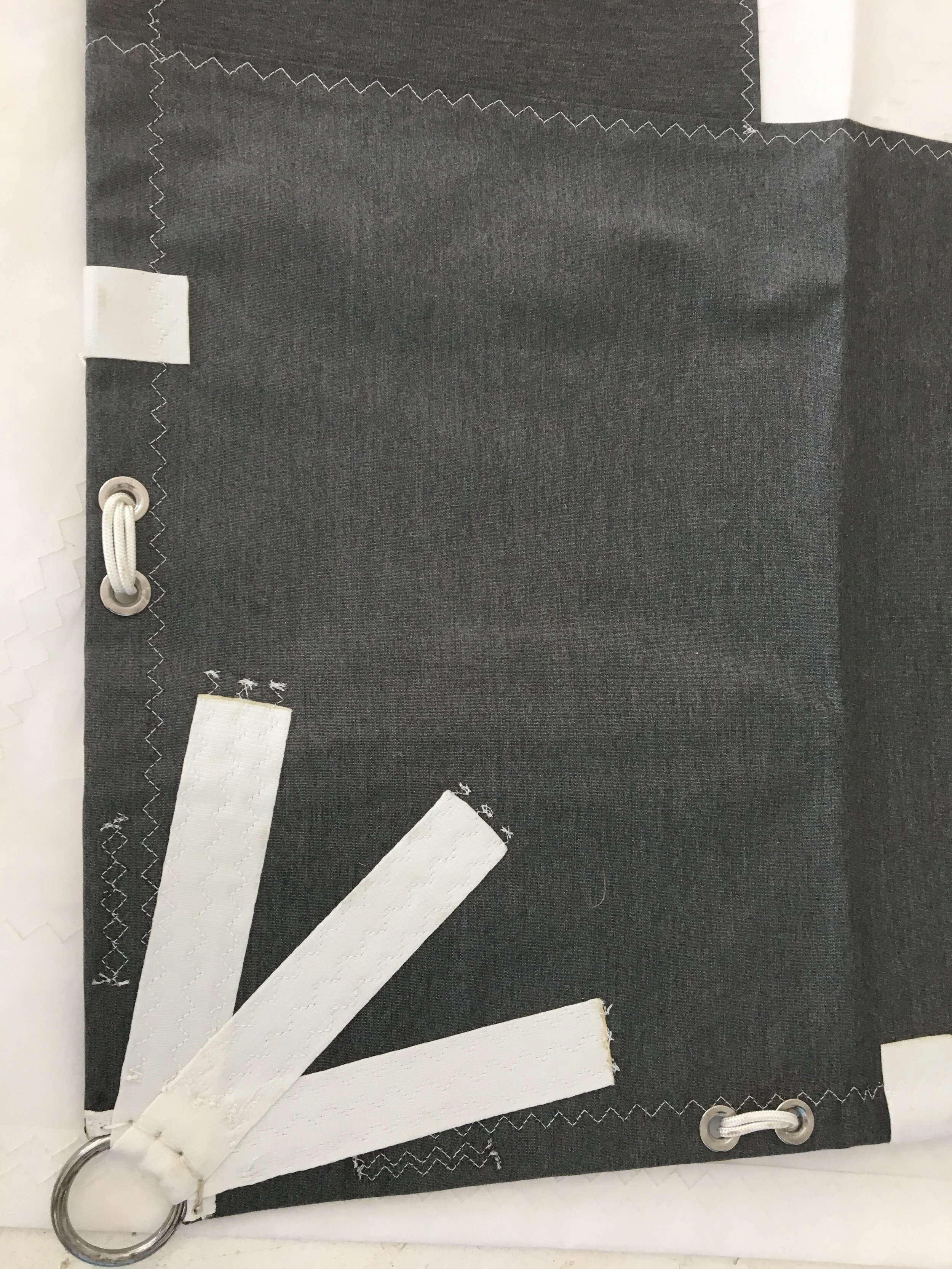

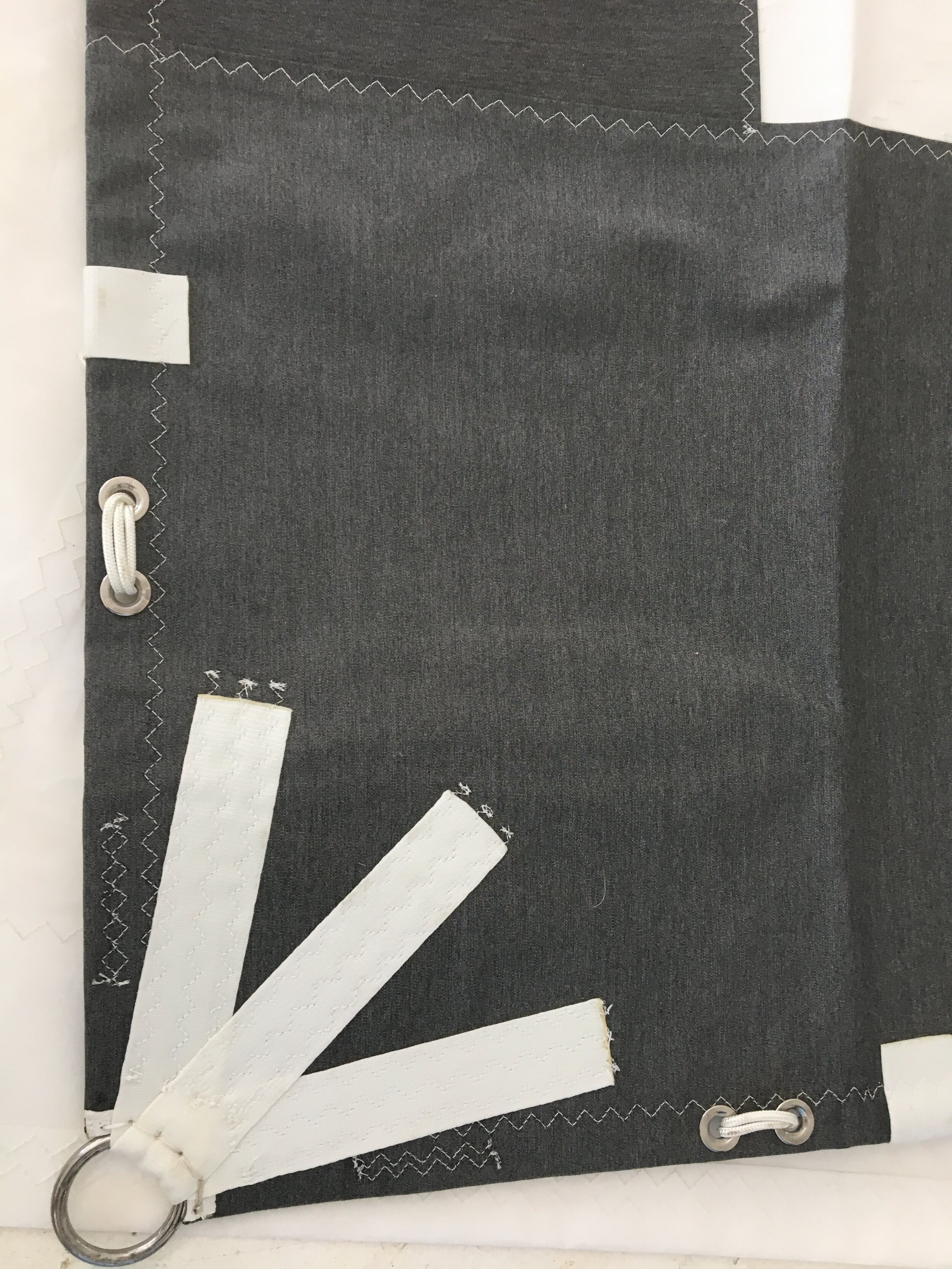

UV Strip Replacement: Prolong the life of your sails by replacing worn or damaged UV strips. This essential maintenance prevents further UV damage and keeps your sails looking new.

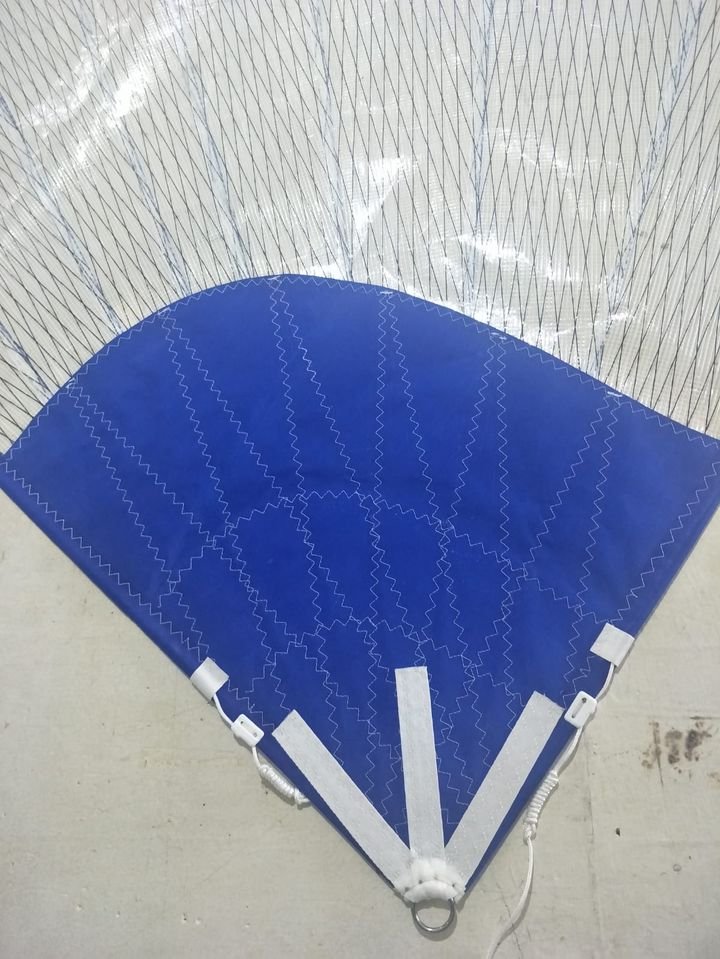

Spinnaker Repairs: Spinnakers are often subject to high stress and can develop rips and tears. Our specialized repair techniques restore your spinnaker's performance and durability.

Mainsail Cleaning and Repair: Over time, mainsails can accumulate dirt, grime, and mildew. We offer thorough cleaning services and expert repairs to ensure your mainsail is in optimal condition.

Awnings, Covers, and Canvas Repairs: In addition to sail repairs, we also provide maintenance and repairs for awnings, covers, and other canvas products. Keep your boat protected and looking great with our comprehensive canvas services.

Why Choose SEA Sailmakers for Sail Repairs?

Unmatched Expertise: With decades of experience, our skilled sailmakers bring extensive knowledge and craftsmanship to every repair project. We understand the intricacies of sail construction and use proven techniques to deliver exceptional results.

Top-Quality Materials: We use only the best materials for our repairs, ensuring durability and performance. From high-strength threads to premium sailcloth, we source the finest materials to match the quality of your original sail.

Convenient Service: Cruising in remote areas can make finding reliable sail repair services challenging. If you're anywhere in Southeast Asia, contact us, and we will arrange for collection and delivery of your sails. Our goal is to provide hassle-free service, so you can focus on enjoying your voyage.

Customer-Centric Approach: At SEA Sailmakers, customer satisfaction is our top priority. Whether you speak to us face-to-face or online, we are dedicated to understanding your needs and delivering personalized solutions. Our friendly and professional team is always ready to assist you.

How to Arrange Sail Repairs

Arranging sail repairs with SEA Sailmakers is simple and convenient. Here’s how you can get started:

Contact Us: Reach out to us via phone, email, or our website to discuss your sail repair needs. Our team will provide an initial assessment and guide you through the process.

Collection and Delivery: If you're cruising anywhere in Southeast Asia, we can arrange for collection and delivery of your sails, ensuring you receive prompt and efficient service.

Repair and Return: Our expert sailmakers will perform the necessary repairs using top-quality materials and techniques. Once completed, we will return your sails to you, ready for action.

Get in Touch

For reliable sail repairs in Southeast Asia, trust South East Asia Sails (SEA Sailmakers). Our commitment to quality, expertise, and customer service ensures your sails receive the best care possible. Contact us today to learn more about our repair services and how we can assist you.

Connect with us: Follow us on Facebook and Instagram for updates, tips, and insights into our latest repair projects and sailing adventures.